Authors: Majed Alzara, M.S., Mohammed Algahtany, M.S., Jacob S. Kashiwagi, PhD., Abdulrahman Al-Tassan, PhD, Dean T. Kashiwagi, PhD, PE

Public projects in Saudi Arabia have faced performance issues. The primary procurement system used in Saudi Arabia (low-bid) does not consider the contractors’ performance. A case study conducted at a university campus in northern Saudi Arabia showed low project performance. The current procurement system was analyzed and modified to utilize the concepts of the Best Value Performance Information Procurement System (BV PIPS). BV PIPS has demonstrated high levels of project performance in previous tests. A large survey was conducted of 761 classified contractors and 43 universities’ representatives. Survey respondents were asked to quantify their view regarding the current procurement system, rate their level of agreement regarding Best Value principles, and rate their level of agreement with the newly proposed procurement system which integrates Best Value principles. The results of the survey show that both, clients and contractors, are dissatisfied with the current procurement system, and agree with the new procurement system. The survey also suggests that respondents agree with Best Value principles suggesting that contractors’ performance should be tracked, and procurement should be conducted using both price and past performance information. The authors recommend that the newly proposed procurement model should be implemented in more projects in Saudi Arabia to further validate the Best Value system and improve the performance of projects in the country.

Keywords: performance, cost, overruns, low-bid, public construction, Saudi Arabia, Best Value, PIPS.

Introduction

The construction industry in Kingdom of Saudi Arabia (KSA) has been developing rapidly over the last 30 years. From 1990–2000, Saudi Arabia spent $234 billion in developing the country’s infrastructure (Cordesman, 2002). The Saudi construction industry has been identified as the largest in the gulf countries, as Saudi spent $575 billion on construction projects from 2008–2013 (Deloitte, 2013). In 2013 alone, the Saudi Ministry of Finance allocated $48 billion for construction projects and $66 billion for 2014 (Arab News, 2014). In 2015, $32 billion was spent on governmental construction projects (Ministry of Finance, 2015). However, researchers over the last three decades have classified the performance of the Saudi construction industry as poor. Three studies have identified that 70% of public construction projects in Saudi Arabia experience delays (Al-Sultan, 1987; Assaf & Al-Hejji, 2006; Zain Al-Abedien, 1983). A study identified that the average delay percentages differed from the original contracts durations in Saudi Arabia by 10% to 30% (Assaf & Al-Hejji, 2006) and in another study by 39% (Elawi, Algahtany, & Kashiwagi, 2016). Furthermore, 80% of the public construction projects in Saudi Arabia faced cost overruns (Al Turkey, 2011). According to Arab News (2011), nonperformance in public construction projects in Saudi Arabia has more than $147 billion at stake. The studies showed that one of the most important factors for the delays was the low-bid procurement system.

Problem

Previous studies have proven that construction performance in Saudi Arabia is poor. The Procurement system is considered a main factor that can increase the performance of projects. Government representatives usually base decisions on price when they procure construction projects. Previous studies have shown that low-bid is considered a major cause of construction project delay in Saudi Arabia (Albogamy, Scott, & Dawood, 2013; Al-Khalil & Al-Ghafly, 1999; Alzara, Kashiwagi, Kashiwagi, & Al-Tassan, 2016; Mahamid, 2013). A case study was conducted in a university in northern Saudi Arabia, which showed delays and cost overrun issues in the university’s construction projects (Alzara et al., 2016). Authors propose that increasing project performance in Saudi Arabia requires reconsidering the procurement delivery system.

Hypothesis

It is proposed that classified contractors and universities’ representatives can improve their performance by implementing Best Value Performance Information Procurement System (BV PIPS) elements in Saudi Arabia.

Study Objectives

Identify the current satisfaction of contractors and universities with the procurement process.

- Use the BV PIPS model concepts to identify how to increase the construction industry performance in KSA.

- Improve the current procurement system by a proposed model based on BV PIPS for KSA.

- Determine if contractors and universities are interested in the new procurement process improvements.

- Identify if the proposed improvements are acceptable for classified contractors and university representatives.

Methodology

A case study of a university in northern Saudi Arabia was used to develop a procurement system to increase the construction project performance. A literature review was conducted on the procurement system and performance of construction projects in Saudi Arabia. The traditional procurement system was compared to the BV PIPS. The current procurement system in the Kingdom of Saudi Arabia (KSA) was studied at the university, and interviews were conducted on the client side, which consisted of procurement, project staff, and the director. A modified version of BV PIPS that could be implemented in Saudi Arabia was proposed. Then a survey was created to identify whether contractors are in agreement with BV PIPS principles. A second survey was given to 761 classified contractors and 43 universities’ representatives, asking about the current model and proposed model. Survey data was evaluated using statistical analysis to show validity and reliability of the results. Based on the results of the survey, and on BV PIPS, the proposed model was created, which can be applied in Saudi Arabia.

Literature Review

Previous researchers have identified that the use of a low bid delivery method based on low price award is a main cause of time overruns in the public construction projects in Saudi Arabia (Albogamy et al., 2013; Al-Khalil & Al-Ghafly, 1999; Assaf & Al-Hejji, 2006; Mahamid, 2013). The selection of contractors based on the lowest bid was identified as the most significant factor of project delay in construction (Banaitiene & Banaitis, 2006; Hatush & Skitmore, 1997a; Holt, Olomolaiye, & Harris, 1995; Huang, 2011; Merna & Smith, 1990; Moore, 1985; Ng & Skitmore, 2001; Plebankiewicz, 2008, 2010; Singh & Tiong, 2006; Waara & Brochner, 2006). According to Herbsman & Ellis (1992), project quality and time are not seen as being as important as the lowest bid. Project performance is affected when vendors are selected based only on the lowest price, while ignoring time and quality (Holt, Olomolaiye, & Harris, 1994). In the United Kingdom, research encouraged the conversion to a performance-based norm from selecting vendors based on a low-bid delivery system, and results showed that the bid prices were not significant (Wong, Holt, & Cooper, 2000). The problem is not the low bids, but that the system of awarding on the low bid allows unqualified contractors to receive awards. Furthermore, a study identified that, regardless of the lowest bid, the selection of qualified contractors among other bidders would have a positive impact on project performance and cost (Iyer & Jha, 2005). When contractors’ selection is based only on the lowest price, unqualified contractors are encouraged to submit bids (Herbsman & Ellis, 1992). As a result, cost and time overruns in projects increase due to the rewarding of projects to unqualified contractors (Banaitiene & Banaitis, 2006; Koushki, Al‐Rashid, & Kartam, 2005). The appropriate awarding to qualified contractors would increase the success rates of construction projects (Alhazmi & McCaffer, 2000; Plebankiewicz, 2009).

The selection of qualified vendors is, unfortunately, considered to be difficult in the low bid award system (Sari & El-Sayegh, 2007). Project owners face complexity in the process of making decisions in selecting qualified contractors (Hatush & Skitmore, 1997b). Similarly, in Saudi Arabia, the selection of qualified contractors in the public sector is further affected by many obstacles, such as the difficulty of decision-making because of a lack of experience, lack of capable consultants, and organizational stress of achieving the targeted projects’ scheduled duration and budget (Al-Busaad, 1997). Another study identified that the selection of qualified contractors is considered a challenge for owner procurement teams, which has a direct effect on the level of satisfaction and project accomplishment (Price & Al-Otaibi, 2010). Experts in the Saudi construction industry have found that the contractor-selection method usually fails to meet clients’ expectations, which causes many issues such as cost overruns, contractor failure, increasing changes, claims, and poor quality (Abu Nemeh, 2012). According to Al-Hazmi (1987), change order modifications, cost overruns, contractor insolvency, and substandard quality are caused when unqualified contractors are awarded projects based on being the lowest price.

A study identified that bidders aim to win by submitting the lowest bid when the competition is based only on price (Cheng, 2008). The possibility that the actual costs of projects are not being represented increases if a cost-based selection of contractors is applied (Olaniran, 2015). Another study showed that a contractor who has the lowest bid usually submits an estimate that is lower than the project’s actual estimated cost (Capen, Clapp, & Campbell, 1971). Consequently, selected contractors based on the lowest-price model face risks of profit loss (Chao & Liou, 2007). Where other bidders would not accept that price, the lowest bidder will commit to the accomplishment of the project (Wolfsetter, 1996). To win bidding competitions in a low-bid procurement delivery method, bidders have used several techniques. Some bidders try to discover mistakes in the bidding documents to assist them in making change orders and claims for further work (Doyle & DeStephanis, 1990). The term predatory bidding refers to this approach, which is used to reduce contractors’ losses (Crowley & Hancher, 1995). Therefore, the actual costs are not reflected in many low-bid projects because of the continuous order changes and claims that bidders use (Bedford, 2009). This method is used by contractors to offset the losses created by submitting a lower bid (Zack, 1993).

A survey of 54 construction experts was conducted in 2015 to identify the causes of low project performance related to cost-based contractor selection. Out of 22 identified causes, the highest ranked cause was that the selected bidders reduced their profit margins. The second cause was the low level of project control and monitoring applied by many contractors. The third cause was the incompetence of selected contractors (Olaniran, 2015). Consequently, in the long term, project quality can be affected when contractors decrease their profit margins (Han, Park, Kim, Kim, & Kang, 2007).

Rather than using the low-bid price method, a new procurement method, BV PIPS, can be adapted in Saudi Arabia to improve performance of projects. BV PIPS has proven to increase performance in construction projects. In this system, expert vendors are selected based on their performance while providing the lowest verified price. The vendors provide, in a Clarification Phase, a detailed proposal that includes the delivery information through detailed preplanning and a representative milestone schedule (Kashiwagi & Kashiwagi, 2011). Alzara et al. (2016) identified the major risk factor in not finishing on time is the lack of preplanning and recognized BV PIPS as a solution for overcoming these time-overrun risk factors.

Best Value and Performance Information Procurement System (BV/PIPS)

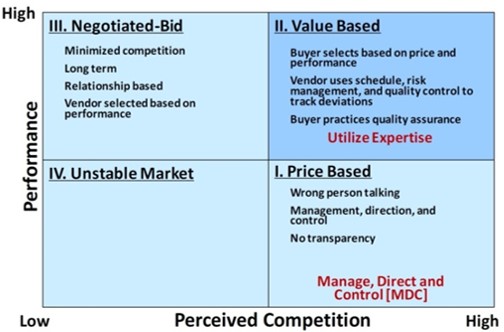

Dr. Dean Kashiwagi created BV PIPS at Arizona State University (ASU) in 1991. BV PIPS has been proven to minimize risks in projects and increase contractors’ performance by using experts (Kashiwagi, Sullivan, & Kashiwagi, 2009; Kashiwagi, Kashiwagi, Sullivan, & Kashiwagi, 2015). BV PIPS applies a special delivery environment that minimizes decision-making and the direction, management, and control of the vendor (Kashiwagi, 1991, 2010). In 2008, the International Council for Building (CIB) Working Commission W117 sanctioned a group (TG61) to perform a study using worldwide literature research to detect innovative approaches in construction that documented an increase in performance of projects (Egbu, Carey, Sullivan, & Kashiwagi, 2008). The study filtered through more than 15 million articles, reviewed more than 4,500 papers, and identified the BV PIPS as the only system that had documented an increase in construction performance on multiple tests. Performance of projects is high when expertise is identified and utilized, and low when the owner attempts to manage, direct and control the contractor. The Industry Structure Model in Figure 1 shows the difference between methods based on value or on price. When the method is value-based, projects show high levels of performance, and when it is based on price, the resulting performance is substandard.

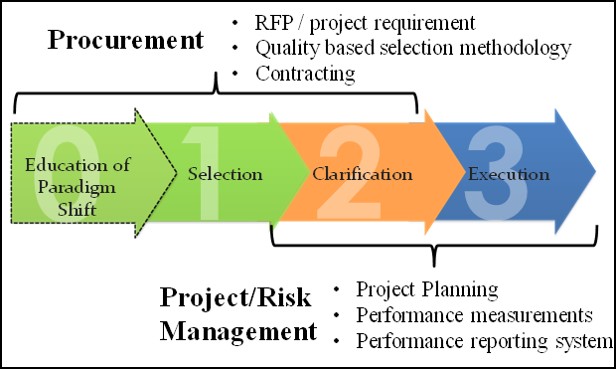

BV PIPS focuses on finding and using expert vendors to increase the performance of projects. The most important performance metrics of PIPS projects is when the client is satisfied. This happened 98% of the time. The projects were completed on budget, on time, and with a high level of quality. PIPS has been tested with over 1,900+ projects with $6.3 billion project value ($4 billion in construction projects and $2.3 billion in non-construction service projects). These projects’ metrics show a 98% rate of success in 6 different countries and 31 states (Kashiwagi, 2014). PIPS increases project performance and efficiency while reducing project risks in comparison with the low-price bid method. The PIPS process shown in Figure 2 consists of four phases: Pre-qualification (optional), Selection, Clarification, and Execution.

The activities of the four phases are:

- Pre-qualification: This optional phase ensures that the contractors meet the minimum requirements and educates the contractors about BV PIPS, and how to submit dominant metrics to prove performance.

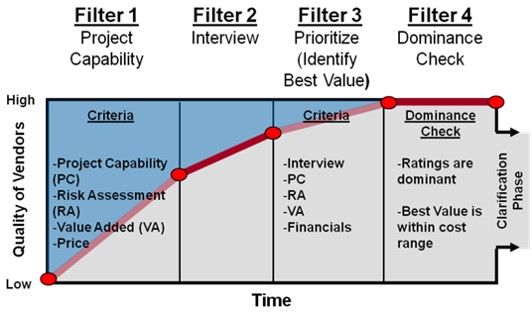

- Selection: This phase has four filters to find the Best Value contractor for a project (see Figure 3). In filter one, contractors should submit project capability and their price, which contains three documents: level of expertise (LE), value added (VA), and risk assessment (RA). Each of the three documents should be a maximum of two pages. The second filter is an interview determining the contractors’ expertise. The interview is for the key visionary experts who can see the project from beginning to the end. The third filter is the committee-prioritized criteria, which weighs the previous steps. Weighting could use numbers from 1–10 or percentages. The fourth filter is a dominance check for the most appropriate contractor who provides information to minimize risk with the lowest cost.

- Clarification: This is the most important phase; the Best Value prioritized contractor will clarify their proposal. The Best Value contractor in this phase should explain what is outside the scope, identify a detailed project cost and time plan, a milestone schedule and a risk mitigation plan.

- Execution: This final phase has the contractor submit a weekly risk report (WRR) to the owner. The WRR is provided as an Excel document that tracks the time and cost deviation to the milestone schedule. The WRR also provides performance measurements and a risk management plan. The Director’s Report (DR) is kept by the owner and contains a summary of all project WRRs and analyses the project information to identify nonperformance and risk.

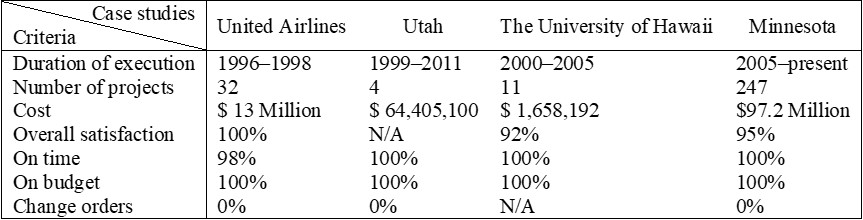

The PIPS process has proven to be successful when applied. Table 1 demonstrates four case studies that used PIPS. These case studies indicate that 100% of the projects that applied PIPS were finished on budget, and most of the projects were accomplished on time. The table shows that there was no change in orders in all the projects, and the overall satisfaction received a high rating from project owners. PIPS considers both performance and cost in the selection of contractors, not just price (CFMA, 2006; Chan & Chan, 2004; Egan, 1998; PBSRG, 2010; Kashiwagi, 2010, 2011).

Best Value Case Studies

The case studies’ results showed a high level of performance when using BV PIPS. The results showed that 100% of projects stayed on budget, and there was no change orders during implementation. The multiple phases in PIPS are used to find the expert vendor who has the highest levels of performance. The projects that used PIPS, were documented to have finished on time and received high satisfaction levels from owners and users. When vendors were selected, the Clarification Phase provided a comprehensive explanation of the vendor’s scope and plan from the start of the project to its end before the projects began. Furthermore, PIPS provided transparency during the execution phase to enhance project performance by using performance measurement and risk management. Conversely, the contractors who won awards in the low-bid approach focused only on price in selecting contractors. The contractors exhibited low performance during the implementation with cost overruns and delay issues. As explained in the literature review, vendors who were awarded low-bid projects submitted low prices just to win contracts and then attempted during implementation to change the project scope through change orders to increase their profit margins.

The strategy of the low-bid method focuses only on the price criterion, whereas PIPS considers both price and performance in finding the best contractor in the selection phase. In addition, it mitigates risks that lead to cost overruns by preplanning, risk mitigation and proper estimation of the cost. The Clarification Phase is the most important phase because the selected vendor must provide a detailed project plan, cost and time schedule, and a risk management plan (RMP) that identifies all risks in the project related to stakeholders (Kashiwagi, 2011). During the execution phase, the vendor must submit a WRR to create transparency with all the stakeholders.

A University Case Study

The university campus chosen for this case study is located in northern Saudi Arabia. This campus serves nearly 26,000 students and consists of 21 colleges in addition to other facilities. The university campus required a number of construction stages to be completed. It was found that of 22 construction projects, 17 were delayed. The university campus should have been completed in 2012; however, only two buildings were operational as of 2015. In July 2015, the university campus was visited by and met with the director and the procurement and project staff to understand the current procurement system and define BV PIPS for the university.

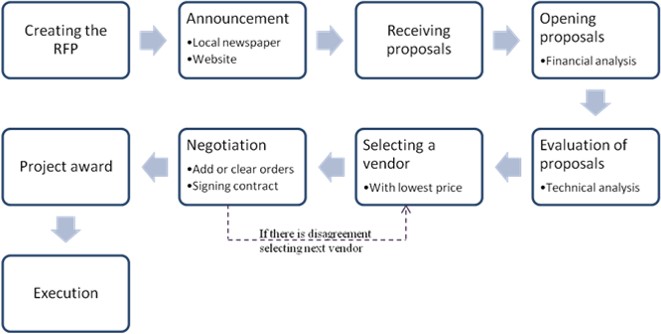

The current procurement system in Saudi Arabia is subject to royal decree number M/58, enacted on September 27, 2006. This system selects bidders based on the lowest price. Tenders and procurement laws include many basic principles and general provisions that consist of 81 articles. To improve the current procurement system, the fundamentals of the system must be understood. Public projects in Saudi Arabia are subjected to nine phases. The first phase involves the request for proposal (RFP). In the second phase, bids are announced in local newspapers and on Web sites. The next phase is that owners receive the proposals and check them to match instructions. Then when the committee and time are identified for opening of sealed-bids, the fourth phase is ready for financial analysis and prioritized by lowest price. In the fifth phase, all proposals should be evaluated by a technical analysis committee. Usually the lowest bidder is selected in the next phase. Then the lowest bidder moves to the negotiation phase with the owner.

In this phase, the committee negotiates the price with the vendor before they sign a contract to add or remove some orders to reach a compromised value. If the vendor and negotiating committee are not able to compromise, the committee should then negotiate with the next bidder. After they sign the contract with the vendor, they move to the next phase, which is the project awarding procedure. Then the vendor moves to the last phase, the execution phase, in which the owner hires consultants to inspect the implementation of the vendor’s work. The current procurement system is shown in Figure 4.

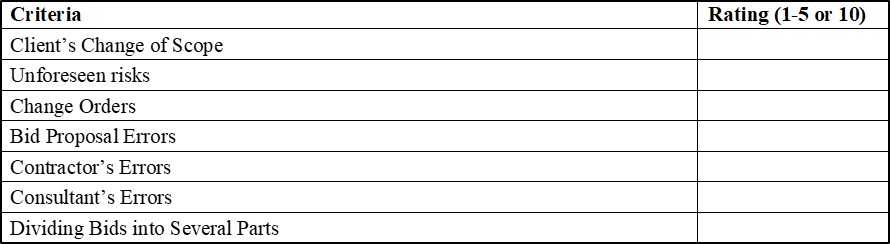

The purpose of this research is to alter the system shown in Figure 4 to allow for the implementation of some of the BV PIPS processes. At the conclusion of this research, the author will adjust Figure 4 accordingly. BV PIPS would introduce several key differences to this procurement process. In Saudi Arabia, the owner has the ability to ask bidders for any requirements that it wants to add to the bid. Based on BV PIPS, it is possible to ask bidders to submit some documents in the evaluation proposals phase. These documents are level of experience (LE), risk assessment (RA), and value added (VA), which help to assess the bidders’ probable performance. Then, the owner can select a bidder with the lowest price and highest performance. When the selected bidder moves to the negotiation or Clarification Phase, then the PM should interview the vendor. Also, the owner can ask the vendor to submit the project’s scope, technical schedule, milestone schedule, and risk management plan. In case the vendor is not qualified for these requirements, the committee should then negotiate with the next bidder. The owner then awards the project and moves to the execution phase. The vendor then submits a WRR and DR during implementation to the client, the Contractors’ Classification Agency, and the National Information Center. The documented data help the owner to anticipate the vendors’ performance in the future.

Survey and Statistical Analysis

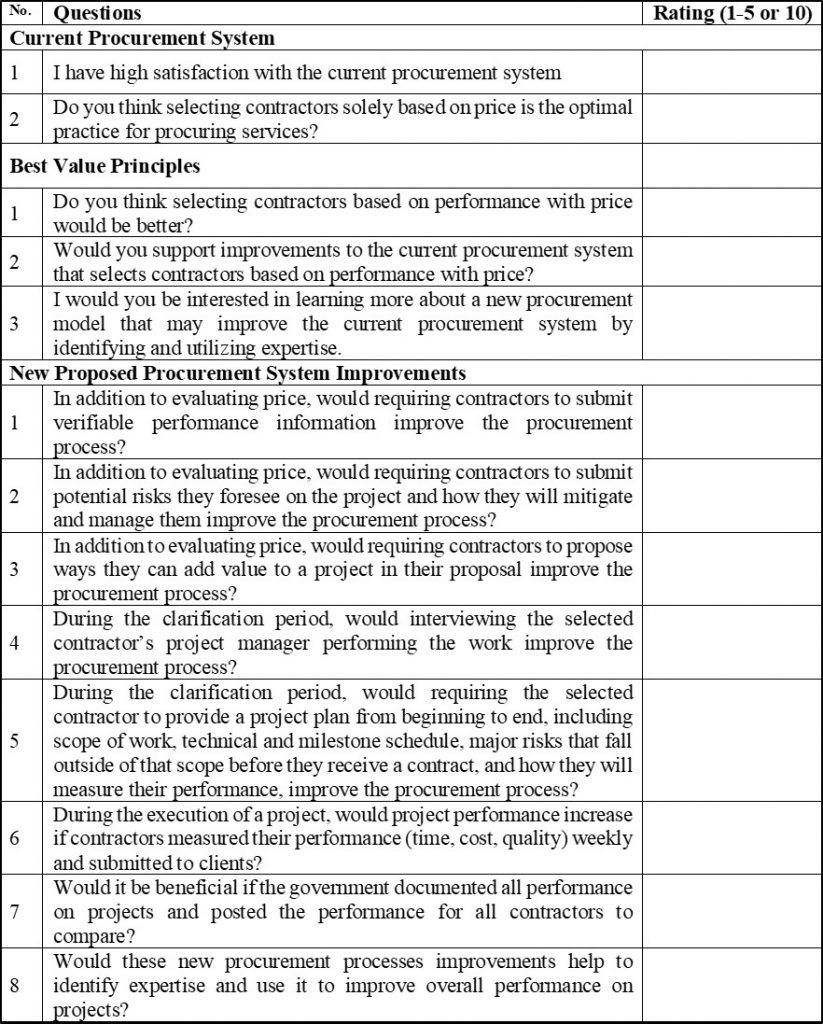

When BV PIPS was discussed with the clients, surveys were created from the principles, phases, and filters of BV PIPS that could be added to the current procurement system (see Appendix A). The survey consisted of three parts: schedule delays, cost overruns causes, and the procurement system. This paper examines the results from the procurement system section. The procurement section consists of 13 questions and statements divided into three categories regarding the current procurement system, Best Value methodology, and the newly proposed procurement system that implements Best Value principles. Survey participants were asked to respond either: “Disagree,” “Don’t Know,” or “Agree.” These responses were coded 1, 5, or 10 respectively.

Surveys were sent to more than 1,500 classified contractors and 14 project departments of universities in Saudi Arabia for rating the current procurement system and to measure the interest level of applying BV PIPS in Saudi Arabia. A total of 761 classified contractors and 43 representatives of universities responded to the survey.

Reliability

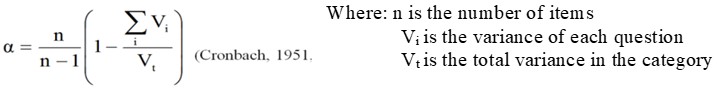

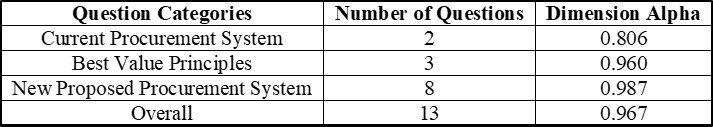

The internal consistency approach for Cronbach’s alpha was used to measure the statistical significance of the responses. The formula for calculating α is:

The values of the internal consistency provided in Table 2 suggest a very meaningful reliability. Generally, a value of 0.60 or greater expresses a strong reliability so the provided values express a high degree of consistency and, consequently, good reliability. Here, also the maximum possible value that may be obtained is 1.

Analysis

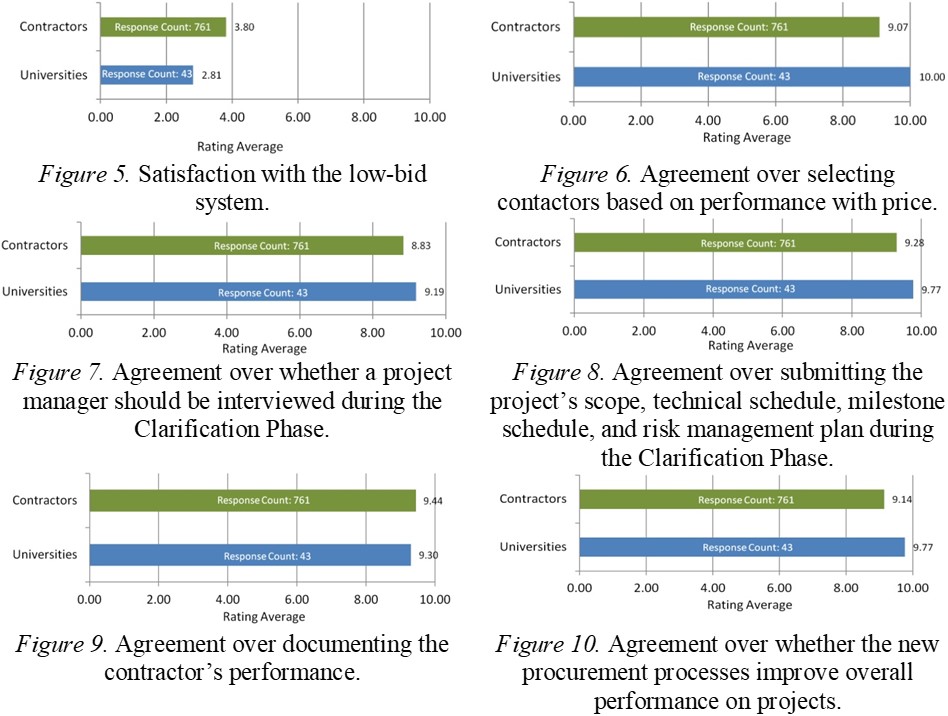

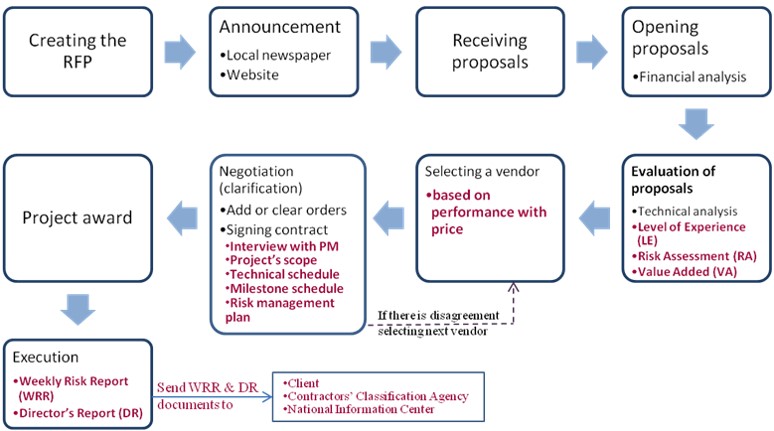

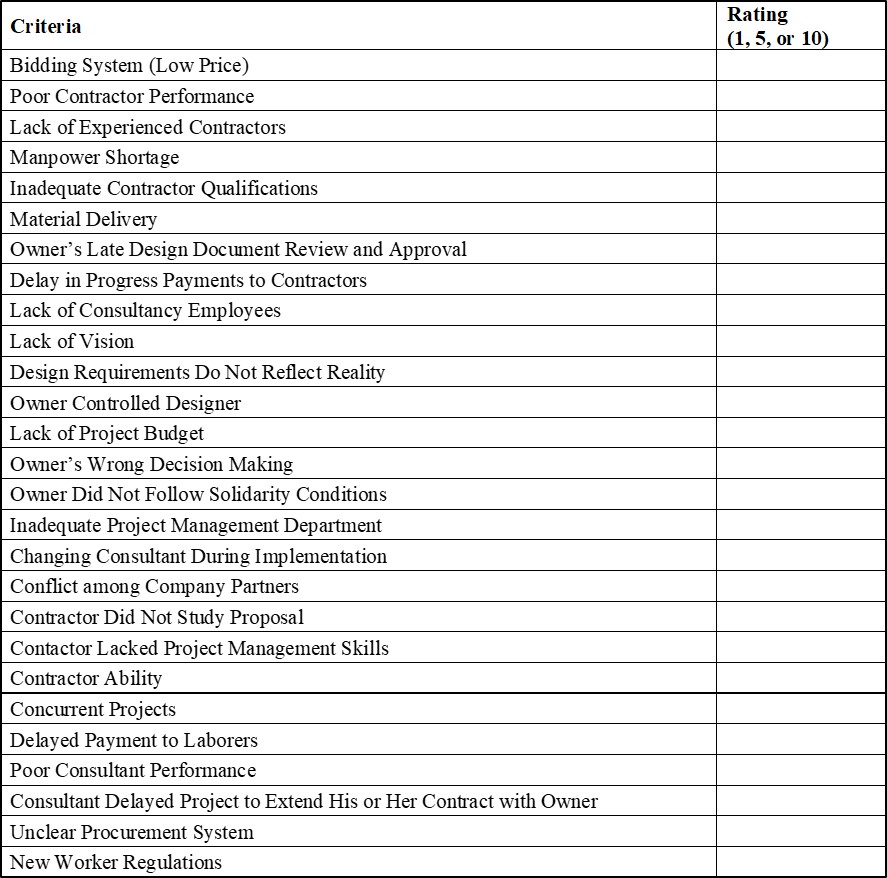

The survey results show that classified contractors and universities’ representatives are not satisfied with the current (low-bid) procurement system. In addition, it shows that contractors and universities’ representatives favor Best Value principles and selecting contactors based on performance information and price. Moreover, in the Clarification Phase, they agree on interviewing the project manager and submitting the project’s scope, technical schedule, milestone schedule, and risk management plan. Figures 5, 6, 7, 8, 9, and 10 outline the survey results of classified contractors and universities’ representatives’ opinions regarding improving the current procurement system.

The proposed procurement system using BV PIPS in Saudi Arabia utilizes the following process:

- The first phase involves the request for proposal (RFP).

- In the second phase, bids are announced in local newspapers and on Web sites.

- In the third phase, owners receive the proposals and check them to match instructions.

- When the committee and time frame are identified for the opening of sealed bids, the fourth phase is ready for financial analysis and is prioritized by lowest price.

- In the fifth and sixth phase, the committee evaluates the level of experience (LE), risk assessment (RA), and value added (VA) documents—each of the three documents should be two pages, maximum. Bidders with low performance should be eliminated, and the committee should select the lowest bidder price among those contractors who have acceptable performance. Committees should use the numbers 1–10 or percentages to weight the three documents and then review all documents of the selected bidder. If the committee finds anything that conflicts with the LE, RA, or VA documents, the committee should eliminate the bidder and select the next one.

- If accepted, the lowest bidder moves to the Clarification phase with the committee. In the seventh phase, the committee should interview the project manager for 15 minutes about the project to see if the project manager is an expert. In addition, the bidder should submit the project’s scope, technical schedule, milestone schedule, and risk management plan. Based on these requirements, the committee should be able to see if the bidder is an expert. If the bidder and committee are not able to find common ground, the committee should then select another bidder.

- After signing the contract with the vendor, the vendor moves to the eighth phase, which is the project awarding procedure.

- In the ninth phase, the vendor moves to the execution phase. Here, the vendor should submit a weekly risk report (WRR) to document the contractor’s performance to the client, the Contractors’ Classification Agency, and the National Information Center. These documents assist in increasing transparency among project parties, which will increase the success of the project.

The summary of the proposed procurement system using BV PIPS is shown in Figure 11.

Conclusion

This research is a case study of the delivery of construction services at a university in northern Saudi Arabia. The performance of the construction has been very poor (not on time and not within cost). The researchers were motivated to identify if their poor construction performance was unique to their university or was it a problem throughout the Kingdom of Saudi Arabia (KSA). This study achieved the following:

- Identified through a literature search that the construction in Saudi Arabia delivered with the low bid approach was non-performing.

- Designed a survey to confirm the causes of low performance in KSA construction industry.

- Conducted the survey among 761 classified contractors and 43 university representatives that conclusively confirmed that the low bid approach was unsuccessful, and that the attributes of the BV PIPS approach should be implemented into the procurement process.

- Designed the implementation of the BV PIPS characteristics into the existing procurement process.

The researchers recommend that this new approach be tested on the future construction projects at the new university.

References

- Abu Nemeh, M. H. A. (2012). Multi-criteria decision making model for the selection of a construction contractor in Saudi Arabia (Unpublished master’s thesis). King Fahd University of Petroleum and Minerals, Saudi Arabia.

- Albogamy, A., Scott, D., & Dawood, N. (2013). Dilemma of Saudi Arabian construction industry. KICEM Journal of Construction Engineering and Project Management, 3(4), 35–40.

- Al-Busaad, S. A. K. (1997). Assessment of application of life cycle cost on construction projects (Unpublished doctoral dissertation). King Fahd University of Petroleum and Minerals, Saudi Arabia.

- Al-Hazmi, M. (1987). Causes of delay in large building construction projects (Unpublished master’s thesis). King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia.

- Alhazmi, T., & McCaffer, R. (2000). Project procurement system selection model. Journal of Construction Engineering and Management, 126(3), 176–184.

- Al-Khalil, M. I., & Al-Ghafly, M .A. (1999). Delay in public utility projects in Saudi Arabia. International Journal of Project Management, 17(2), 101–106.

- Al-Sultan, A. S. (1987). Determination of construction contract duration for public projects in Saudi Arabia (Unpublished master’s thesis). King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia.

- Al Turkey, T. (2011). The reality of projects in terms of organization and structure, and the reasons for success and failure In Saudi Arabia. Retrieved from http://www.alwatan.com.sa/Local/News_Detail.aspx?ArticleID=49126&CategoryID=5

- Alzara, M., Kashiwagi, J., Kashiwagi, D., & Al-Tassan, A. (2016). Important causes of delayed projects in Saudi Arabia vs. PIPS: A university campus case study. Journal for the Advancement of Performance Information & Value, 8(1).

- Arab News. (2011, December 23). Projects worth SR550bn stalled, contractors ask government to step in. Gulf in the Media.

- Arab News. (2014, January 4). Debate over delays in public projects. Access World News. Retrieved from http://docs.newsbank.com.ezproxy1.lib.asu.edu/openurl?ctx_ver=z39.88-2004&rft_id=info:sid/iw.newsbank.com:AWNB:SANJ&rft_val_format=info:ofi/fmt:kev:mtx:ctx&rft_dat=14B2444B657C7F20&svc_dat=InfoWeb:aggregated5&req_dat=0D0CB4EB19340F80

- Assaf, S. A., & Al-Hejji, S. (2006). Causes of delay in large construction projects. International Journal of Project Management, 24(4), 349–357.

- Banaitiene, N., & Banaitis, A. (2006). Analysis of criteria for contractors’ qualification evaluation. Technological and Economic Development of Economy, 12(4), 276–282.

- Bedford, T. (2009). Analysis of the low-bid award system in public sector construction procurement (Unpublished doctoral dissertation). University of Toronto, Canada.

- Capen, E. C., Clapp, R. V., & Campbell, W. M. (1971). Competitive bidding in high-risk situations. Journal of Petroleum Technology, 23(6), 641–653.

- CFMA. (2006). Construction industry annual financial survey. Moss-Adams, LLP (18th ed.).

- Chan, A. P., & Chan, A. P. (2004). Key performance indicators for measuring construction success. Benchmarking: An International Journal, 11(2), 203–221.

- Chao, L. C., & Liou, C. N. (2007). Risk‐minimizing approach to bid‐cutting limit determination. Construction Management and Economics, 25(8), 835–843.

- Cheng, C. B. (2008). Solving a sealed-bid reverse auction problem by multiple-criterion decision-making methods. Computers & Mathematics with Applications, 56(12), 3261–3274.

- Cordesman, A. H. (2002). Saudi Arabia enters the 21st century: Economic, demographic and social challenges. Washington, DC: Center for Strategic and International Studies.

- Crowley, L. G., & Hancher, D. E. (1995). Risk assessment of competitive procurement. Journal of Construction Engineering and Management, 121(2), 230–237.

- Deloitte. (2013). GCC powers of construction 2013: Construction sector overview. Retrieved from https://www.deloitte.com/assets/DcomMiddleEast/Local%20Assets/Documents/Industries/Real%20Estate/Construction/me_r eal-estate_gcc_construction_ppt_13.pdf

- Doyle, W. J., & DeStephanis, A. (1990). Preparing bids to avoid claims. Construction Bidding Law, 17–45.

- Egan, S. J. (1998). Rethinking construction: The report of the Construction Task Force to the Deputy Prime Minister, John Prescott, on the scope for improving the quality and efficiency of UK construction. The Department of the Environment, Transport and the Regions.

- Egbu, C., Carey, B., Sullivan, K., & Kashiwagi, D. (2008). Identification of the use and impact of performance information within the construction industry. The International Council for Research and Innovation in Building and Construction (CIB TG61), Arizona, USA, 36.

- Elawi, G. S. A., Algahtany, M., & Kashiwagi, D. (2016). Owners’ perspective of factors contributing to project delay: Case studies of road and bridge projects in Saudi Arabia. Procedia Engineering, 145, 1402–1409.

- Han, S. H., Park, S. H., Kim, D. Y., Kim, H., & Kang, Y. W. (2007). Causes of bad profit in overseas construction projects. Journal of Construction Engineering and Management, 133(12), 932–943.

- Hatush, Z., & Skitmore, M. (1997a). Criteria for contractor selection. Construction Management & Economics, 15(1), 19–38.

- Hatush, Z., & Skitmore, M. (1997b). Evaluating contractor prequalification data: Selection criteria and project success factors. Construction Management and Economics, 15(2), 129–147.

- Herbsman, Z., & Ellis, R. (1992). Multiparameter bidding system—Innovation in contract administration. Journal of Construction Engineering and Management, 118(1), 142–150.

- Holt, G. D., Olomolaiye, P. O., & Harris, F. C. (1994). Evaluating performance potential in the selection of construction contractors. Engineering, Construction and Architectural Management, 1(1), 29–50.

- Holt, G. D., Olomolaiye, P. O., & Harris, F. C. (1995). A review of contractor selection practice in the UK construction industry. Building and Environment, 30(4), 553–561.

- Huang, X. (2011). An analysis of the selection of project contractor in the construction management process. International Journal of Business and Management, 6(3), 184.

- Iyer, K. C., & Jha, K. N. (2005). Factors affecting cost performance: Evidence from Indian construction projects. International Journal of Project Management, 23(4), 283–295.

- Kashiwagi, D. T. (1991). Development of a Performance Based Design/Procurement System for Nonstructural Facility Systems. Tempe, Arizona: Arizona State University.

- Kashiwagi, D. (2010). Best Value PIPS/PIRMS. Performance Based Studies Research Group. Kashiwagi Solution Model Inc., Mesa, AZ.

- Kashiwagi, D. (2011). Case study: Best Value procurement/performance information procurement system development. Journal for the Advancement of Performance Information & Value, 3(1).

- Kashiwagi, D. (2014). Information measurement theory with the “Kashiwagi Story.” Retrieved from www.KSM-Inc.com.

- Kashiwagi, D., & Kashiwagi, J. (2011). Case study: Performance information procurement system (PIPS) in the Netherlands. Malaysian Construction Research Journal, 8(1).

- Kashiwagi, J., Sullivan, K., & Kashiwagi, D. T. (2009). Risk management system implemented at the US Army Medical Command. Journal of Facilities Management, 7(3), 224–245.

- Kashiwagi, D., Kashiwagi, J., Sullivan, K., Kashiwagi, I. (2015). The Development of the Best Value Approach in the State of Minnesota. Journal for the Advancement of Performance Information & Value, 7 (1).

- Koushki, P. A., Al‐Rashid, K., & Kartam, N. (2005). Delays and cost increases in the construction of private residential projects in Kuwait. Construction Management and Economics, 23(3), 285–294.

- Mahamid, I. (2013). Contributions to schedule delay in public construction projects in Saudi Arabia: Owners’ perspective. Journal of Construction Project Management and Innovation, 3(2), 608–619.

- Merna, A., & Smith, N. J. (1990). Bid evaluation for UK public sector construction contracts. ICE Proceedings, 88(1), 91–105.

- Ministry of Finance. (2015, December 28). Recent economic developments and highlights of fiscal years 1436/1437 (2015) & 1437/1438 (2016), Saudi Arabia. Retrieved from https://www.mof.gov.sa/English/DownloadsCenter/Budget/Ministry’s%20of%20Finance%20statment%20about%20the%20national%20budget%20for%202016.pdf.

- Moore, M. J. (1985). Selecting a contractor for fast-track projects part 1. Principles of contractor evaluation. Plant Engineering, 39(12), 74–75.

- Ng, S. T., & Skitmore, R. M. (2001). Contractor selection criteria: A cost–benefit analysis. IEEE Transactions on Engineering Management, 48(1), 96–106.

- Olaniran, O. J. (2015). The effects of cost-based contractor selection on construction project performance. Journal of Financial Management of Property and Construction, 20(3), 235–251.

- PBSRG. (2010). Performance Based Studies Research Group Internal Research Documentation (Unpublished raw data). Arizona State University.

- Plebankiewicz, E. (2008). Criteria of contractor selection used by Polish investors. Journal of Civil Engineering and Management, 15(4), 377–385.

- Plebankiewicz, E. (2009). Contractor prequalification model using fuzzy sets. Journal of Civil Engineering and Management, 15(4), 377–385.

- Plebankiewicz, E. (2010). Construction contractor prequalification from Polish clients’ perspective. Journal of Civil Engineering and Management, 16(1), 57–64.

- Price, A. D., & Al-Otaibi, M. (2010). Analysis and evaluation of criteria for pre-selecting contractors in the Saudi Arabian construction sector. In C. Egbu (Ed.), Proceedings 26th Annual ARCOM Conference, 6–8 September 2010 (pp. 1141–1148). Leeds, UK. Association of Researchers in Construction Management (vol. 2).

- Sari, A., & El-Sayegh, S. (2007). Factors affecting the selection of the appropriate construction management at-risk contractor. Paper presented at the Fifth LACCEI International Latin American and Caribbean Conference for Engineering and Technology, (LACCEI 2007).

- Singh, D., & Tiong, R. L. (2006). Contractor selection criteria: Investigation of opinions of Singapore construction practitioners. Journal of Construction Engineering and Management, 132(9), 998–1008.

- Waara, F., & Bröchner, J. (2006). Price and nonprice criteria for contractor selection. Journal of Construction Engineering and Management, 132(8), 797–804.

- Wolfsetter, E. (1996). Auctions: An introduction. Journal of Economic Surveys, 1(4), 367–420.

- Wong, C. H., Holt, G. D., & Cooper, P. A. (2000). Lowest price or value? Investigation of UK construction clients’ tender selection process. Construction Management & Economics, 18(7), 767–774.

- Zack, J. G. (1993). “Claimsmanship”: Current perspective. Journal of Construction Engineering and Management, 119(3), 480–497.

- Zain Al-Abedien, H. M. (1983). About the effect of delay penalty on the construction of projects and modification proposals. Proceedings from the First Saudi Engineering Conference. Jeddah, 14–19.

Appendix A

Survey

Part 1 Instructions: Please rate project delay causes in Saudi Arabian universities, with 1 meaning “not common,” 5 meaning “don’t know,” and 10 meaning “common.” Please only use one of these three choices for each question.

Part 2 Instructions: please rate the causes of cost overruns to projects in Saudi Arabian universities, with 1 meaning “not common,” 5 meaning “don’t know,” and 10 meaning “common.” Please only use one of these three choices for each question.

Part 3 Instructions: please fill in the survey below by providing a rating per question. 1 means you “disagree,” 5 means you “don’t know,” and 10 means you “agree.” Please only use one of these three choices for each question.